Nkọwa

Isi ojiji nke efere ígwè na-eguzogide iyi na-ebubata:

1) Igwe na-ewu ihe na akụrụngwa: loader bulldozer excavator bucket plate, side agụba efere, ịwụ ala efere, agụba, efere.

2) Nbudata ma na-ebutu igwe na akụrụngwa: na-ebutu efere igwe ihe igwe, efere mkpuchi hopper, efere agụba, efere na-ebugharị akpaka akpaghị aka.

3) Ngwa igwe na akụrụngwa: ciment pusher eze efere, ihe igwekota igwekota efere, agwakọta n'ala lining efere, uzuzu na-anakọta lining efere.

4) Metallurgical igwe na akụrụngwa: ígwè ore sintering ebuga ikiaka, ígwè ore sintering igwe lining efere, scraper igwe lining efere.

5) Ngwuputa igwe na akụrụngwa: efere mkpuchi nke igwe na-egwuputa ihe.

6) Ngwá ọrụ ndị ọzọ: igwe igwe igwe, agụba, akụkụ dị iche iche na-eguzogide nke igwe ọdụ ụgbọ mmiri

7) Thermal ike akụrụngwa: coal-egwe ọka lining osisi, coal scutcher, coal nnyefe ọkpọkọ, coal nkesa efere, coal unloading akụrụngwa lining osisi.

8) Ngwa igwe na-agba agba agba agba: efere mkpuchi nke igwe agba agba agba

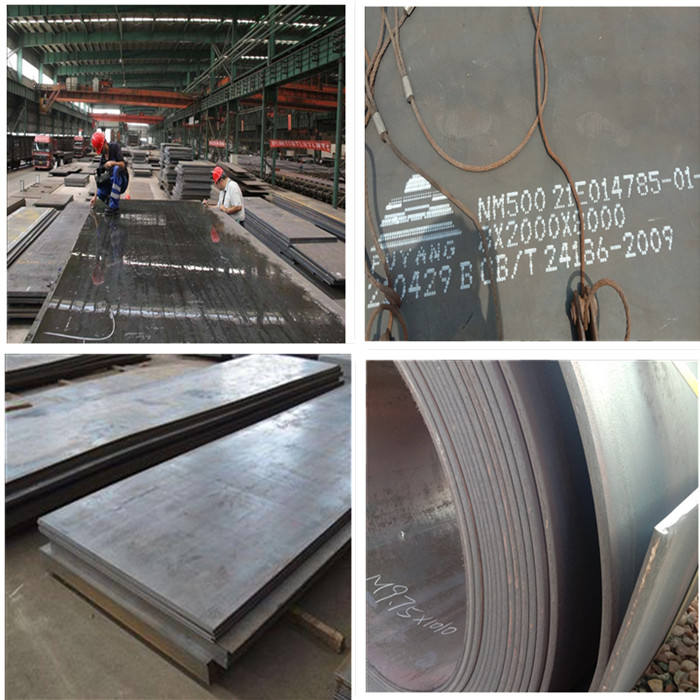

Ebe ọ bụ na ya guzosie ike, ụlọ ọrụ kemgbe ka àgwà nke ngwaahịa dị ka isi nlanarị nke Enterprise, àgwà nke ọrụ dị ka àkwà mmiri anyị ihe ịga nke ọma anyị ji ezi obi na-atụ anya guzobe azụmahịa mmekọrịta na ndị ahịa anyị, na-enye àgwà ọrụ, na ndi oru itumgbere ahia, mmepe nkịtị.

Site na-aga n'ihu ọganihu, ọhụrụ, nke mere na àgwà larịị nke ngwaahịa anyị ịnọgide na-enwe na ụzọ nke ụlọ ọrụ.

Ebumnuche dị mma: 98% nke ngwaahịa na-agafe nyocha mbufe mbu, 0.2% nke ngwaahịa ndị dị n'elu na-agafe nyocha mbufe mbu kwa afọ, 100% nke ngwaahịa na-agafe ụlọ ọrụ mmepụta ihe.

"Iguzosi ike n'ezi ihe, ịchọ eziokwu, mmepe, ihe ọhụrụ" bụ ebumnuche azụmahịa nke ụlọ ọrụ anyị ruo ọtụtụ afọ, jiri obi ụtọ na-anabata ọtụtụ ndị ọrụ igwe anaghị agba nchara na ndị ọrụ ibe anyị ka ha gaa leta ụlọ ọrụ anyị, n'ihi na ihe na-eyi efere na-emepụta ọmarịcha.

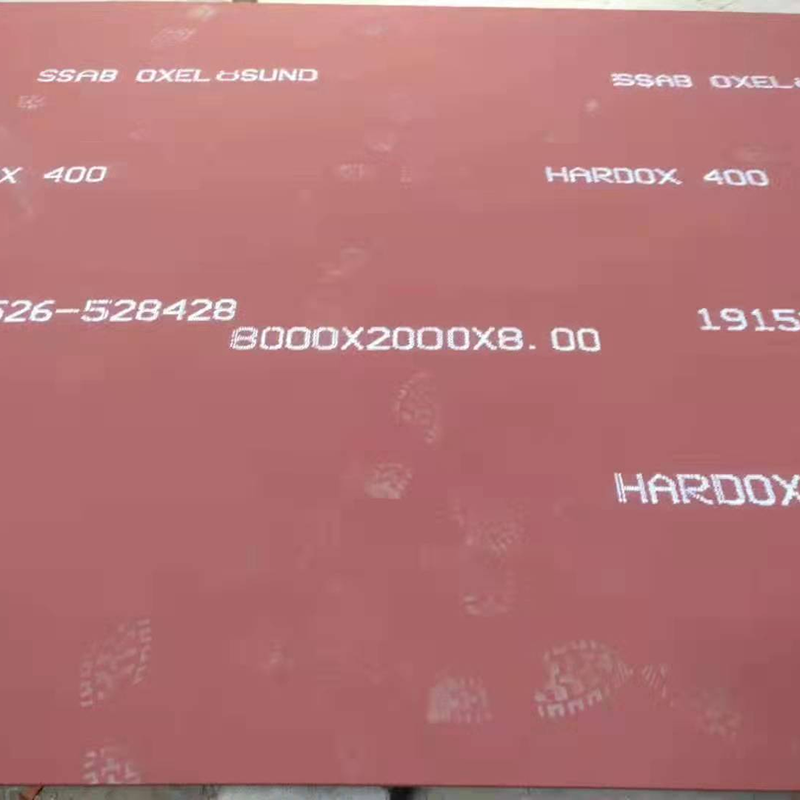

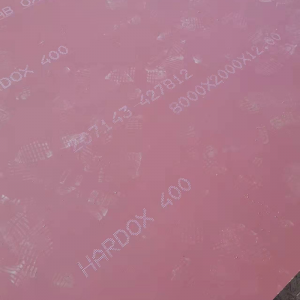

efere ígwè na-eguzogide iyi

| Ọkwa | NM360/NM400/NM450/NM500/RAEX400/RAEX450/RAEX500/NM360,BHNM400,BHNM450,BHNM500,BHNM550,BHNM600,BHNM650,N0D,N0D,N0D |

| Ọkpụrụkpụ | 3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+6,8+7,8+8,10+4,10+ 5,10+6,10+7,10+8,10+9,10+10,10+20,12+4,12+5,12+6,12+7,12+8,12+9, 12+1,12+11,12+12, 12+17,14+6,14+8,14+10,16+6,16+8,16+10,18+6,18+8,18+10,20+5,20+6,20+ 8,20+10,20+20,30+10,40+10, ahaziri |

| Obosara | 1500/2000/2500/3000MM |

Ngwaahịa ndị ọzọ

1. Magburu onwe eyi iguzogideNgwakọta kemịkalụ nke oyi akwa na-eguzogide alloy nwere ọdịnaya carbon nke 4 ruo 5% yana ọdịnaya chromium nke 25 ruo 30%.Akụkụ olu nke Cr7C3 carbides na nhazi metallographic karịrị 50%.Isi ike nke macroscopic bụ HRC56 ruo 62. Isi ike bụ HV1400~1800. N'ihi na a na-ekesa carbides perpendicularly na ntụziaka nke iyi, ọbụna ma e jiri ya tụnyere nkedo alloys nke otu ihe mejupụtara na ike siri ike, ihe mgbochi na-eguzogide ihe karịrị okpukpu abụọ.Ntụnyere na iyi nguzogide nke ọtụtụ ihe ahụkarị bụ ndị a: (1) Na obere carbon ígwè;20~25:1 (2) Na ihe nkedo nke chromium dị elu;1.5~2.5:1

2. Mmetụta mmetụta dị mmaIhe dị n'ala nke efere nchara na-eguzogide oyi bụ obere carbon ígwè ma ọ bụ obere alloy.Ihe siri ike dị ka igwe anaghị agba nchara na-egosipụta ịdị elu nke bimetal.Ngwunye na-eguzogide ọgwụ na-eguzogide ihe na-eyi uwe na-eyi, na mkpụrụ ahụ na-ebu ibu nke usoro ahụ, ya mere ọ nwere mmetụta dị mma na-eguzogide.Ọ nwere ike iguzogide mmetụta na iyi nke elu dobe hopper na usoro nnyefe ihe.

3. Ezigbo okpomọkụ na-eguzogideA na-atụ aro oyi akwa na-eguzogide alloy n'okpuru ≤600℃.Ọ bụrụ na etinye vanadium, molybdenum na alloys ndị ọzọ na alloy wear-eguzogide oyi akwa, ọ nwere ike idi elu okpomọkụ eyi nke ≤800 ℃.The na-atụ aro na-arụ ọrụ okpomọkụ dị ka ndị a: Nkịtị carbon ígwè base efere na-atụ aro na-eji n'okpuru na-arụ ọrụ ọnọdụ nke adịghị elu karịa 380 ℃;Obere alloy okpomọkụ na-eguzogide ígwè efere (15CrMo, 12Cr1MOV, wdg) na-atụ aro na-eji substrates na-arụ ọrụ ọnọdụ adịghị elu karịa 540 ℃;A na-atụ aro ka ejiri igwe anaghị agba nchara na-ekpo ọkụ na-ekpo ọkụ na-erughị 800C.

4. Ezi nguzogide corrosionIhe mkpuchi alloy nke efere nchara mejupụtara nke na-eyi na-eguzogide ọgwụ nwere pasent dị elu nke chromium dara, ya mere ọ nwere ogo ụfọdụ nke nchara na nguzogide corrosion.Enwere ike iji ya gbochie ịrapagidesi ike na coal mgbe ejiri ya na mkpọsa coal na mkpọ.

5. Ụdị zuru oke na nkọwapụtaEfere ígwè na-eguzogide iyi nwere nkọwa zuru ezu na ọtụtụ ụdị, ma ghọọ usoro azụmahịa.Ọkpụrụkpụ nke oyi akwa alloy na-eguzogide iyi bụ 3-20mm.Ọkpụrụkpụ nke efere nchara mejupụtara bụ ma ọ dịkarịa ala 6mm, ọ bụghịkwa oke oke.Enwere ike ịnye efere ígwè na-eguzogide ọkọlọtọ na 1200 ma ọ bụ 3800 × 12000mm, a pụkwara ịhazi ya dịka nha nke eserese dị ka mkpa onye ọrụ si dị.A na-ekewa efere ígwè na-adịghị eyi uwe n'ime ụdị atọ: ụdị nkịtị, ụdị na-eguzogide mmetụta na ụdị okpomọkụ dị elu.Ekwesịrị ịkọwapụta iwu akwa akwa akwa na-eguzogide oyi na mmetụta na-eguzogide ọgwụ nchara nchara.

6. Ịrụ ọrụ nhazi dị mmaEnwere ike ịkpụ, gbadaa ma ọ bụ kpụọ, welded na ọkpọ, na-esikwa ya n'akụkụ dị iche iche nke a na-eji efere ígwè nkịtị na-edozi ya.Efere ígwè ndị a na-akpụ akpụ na-eguzogide nwere ike ịdekọ ya n'ime akụkụ akụkụ ma ọ bụ akụkụ dị iche iche nke injinịa.

7. Ọrụ na atụmatụEnwere ike welded ma nwee ezigbo mgbochi iyi..